In the fast-paced manufacturing sector, the decision to upgrade control systems is often met with hesitation. The philosophy of “if it isn’t broken, don’t fix it” prevails in many factories, leaving aging control cabinets untouched for decades. However, maintaining a legacy industrial PLC (Programmable Logic Controller) is not a cost-free strategy; it is a financial risk that grows exponentially over time. As components become obsolete and connectivity demands increase, the hidden costs of legacy systems begin to outweigh the initial investment of upgrading. By analyzing the tangible benefits of modern platforms, such as those offered by Leadshine, companies can see that an upgrade is not just an expense—it is a critical investment in future profitability.

The Hidden Costs of Legacy Maintenance

The most immediate financial argument against keeping an outdated industrial PLC is the rising cost of maintenance. As hardware ages, failure rates increase, leading to unplanned downtime that can cost manufacturers thousands of dollars per minute in lost production. Furthermore, sourcing replacement parts for discontinued models often forces companies to pay premium prices on the grey market. A modern system eliminates this scarcity premium. Leadshine offers a robust supply chain and readily available components, ensuring that maintenance budgets are spent on preventative measures rather than emergency firefighting. The cost of a single prolonged outage due to a failed, irreplaceable CPU often exceeds the price of a full system upgrade.

Enhancing Performance and Throughput

Beyond mere availability, modern controllers offer performance capabilities that legacy systems cannot match. Older PLCs operate with cycle times measured in tens of milliseconds, which limits machine speed and throughput. In contrast, the modern industrial PLC solutions detailed on the Leadshine product page, such as the MC and LC series, boast nanosecond-level instruction processing speeds. This drastic increase in processing power allows for more complex algorithms and tighter control loops, directly translating to higher machine speeds and increased units per hour. For a high-volume manufacturer, a 10% increase in throughput driven by a faster controller yields a return on investment (ROI) that pays for the upgrade in a matter of months.

The Integration of Logic and Motion

One of the most significant cost-saving advancements in modern automation is the convergence of disciplines. Historically, a machine required a PLC for logic and a separate motion controller for servos, doubling the hardware cost and complexity. Modern platforms, specifically the MC series from Leadshine, integrate advanced motion control functionalities—such as linear interpolation, circular interpolation, and electronic cams—directly into the PLC. For a PLC OEM (Original Equipment Manufacturer), this integration reduces the Bill of Materials (BOM) significantly. By replacing two expensive devices with a single, unified controller, OEMs can offer more competitive pricing to their end-users while simultaneously simplifying their own inventory and assembly processes.

Connectivity and the IIoT Advantage

Legacy PLCs were designed as isolated islands of automation, often using proprietary communication protocols that make data extraction difficult or impossible. In the era of Industry 4.0, data is a valuable asset. Modern controllers act as edge gateways, supporting open industrial Ethernet standards like EtherCAT, Modbus TCP, and CANopen. Leadshine PLCs are engineered with this connectivity as a standard feature, allowing seamless integration with upper-level SCADA (Supervisory Control and Data Acquisition) and ERP systems. The benefit here is operational visibility; real-time data allows for predictive maintenance and energy monitoring, unlocking cost savings that were invisible in the legacy “black box” architecture.

Scalability for Future Growth

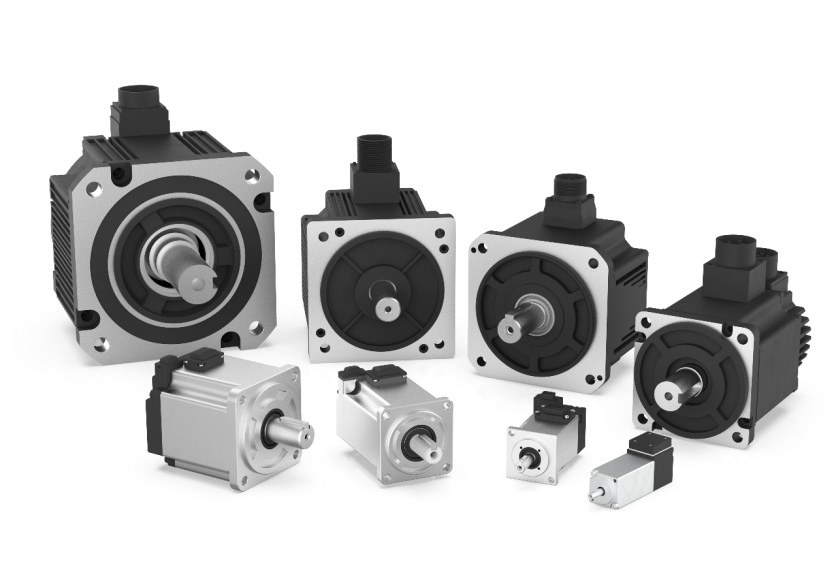

A major limitation of older systems is their rigidity; adding new functionality often requires a complete hardware overhaul. Modern architectures are inherently modular and scalable. The Leadshine product portfolio is segmented into the Small (SC series), Medium (MC series), and Large (LC series) categories to address this exact need. An engineer can start with a compact SC series unit for a simple station and easily scale up to an MC series for a complex multi-axis line without learning a new programming environment. This scalability protects the initial investment, allowing the system to grow alongside the business rather than becoming a bottleneck that necessitates a “rip-and-replace” approach.

Reducing Engineering and Development Time

Time is a currency in engineering. Legacy systems often rely on outdated, clunky programming software that lacks modern debugging tools. Modern Leadshine PLCs support the IEC 61131-3 standard, allowing programmers to work in familiar languages like Structured Text (ST), Ladder Diagram (LD), and Function Block Diagram (FBD). For a PLC oem, this standardization drastically reduces software development and commissioning time. Reusable function blocks and integrated simulation tools allow for faster prototyping and deployment. When engineering hours are factored into the cost-benefit analysis, the efficiency gains from a modern development environment contribute significantly to the overall savings.

Space Savings and Cabinet Real Estate

Factory floor space is often at a premium, and large, bulky legacy cabinets consume valuable real estate. Early generation PLCs and their associated relay banks were massive. Modern electronics have miniaturized these components significantly. The slice-type I/O modules and compact CPU designs found in Leadshine series allow for much smaller control cabinets. This reduction in physical footprint is particularly valuable for a PLC oem building compact machinery or for factories looking to optimize their floor layout. Smaller cabinets also mean lower enclosure costs and reduced shipping weights, adding another layer of indirect cost savings to the project.

The Verdict on Upgrading

When all factors are weighed—maintenance reduction, throughput increases, BOM consolidation, and engineering efficiency—the cost-benefit analysis heavily favors upgrading. Clinging to a legacy industrial PLC is a strategy of diminishing returns, where the risks of failure and the costs of stagnation eventually overwhelm the perceived savings of delaying the investment. By partnering with a forward-thinking supplier like Leadshine, manufacturers and OEMs can transition to a modern platform that not only solves today’s problems but secures their competitive edge for the future. The question is no longer if you can afford to upgrade, but whether you can afford not to.